2021年3月15日 This part describes the history, goals of pelletization, and provides a framework so that the chemical factors leading into an effective pelletizing process can be understood. The general overview of binders is covered to provide an outline of what

Read More

2018年7月11日 Pelletizing of iron ore concentrate is one of the proven agglomeration technologies. Pellet production has increased dramatically

Read More

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries.

Read More

2022年1月1日 Abstract. A brief introduction to recent developments in iron ore pelletizing is provided in this chapter, including the world output of fired pellets, pellet production

Read More

2015年1月1日 The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance

Read More

2015年12月31日 The iron ore pelletizing process has been studied by using a statistical mathematical model to predict and optimize the sintering conditions of magnesteltic

Read More

2020年3月28日 Iron ore pellet production requires a fine mineral particle distribution to lead to good agglomerate densification, a smooth surface, and controlled growth in the

Read More

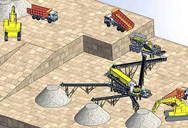

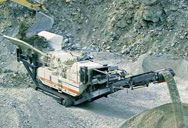

2022年5月5日 The pelletizing process, where the crude ore from the mine is upgraded, involves several steps, including grinding, balling, and induration; see Figure 1 to the left.

Read More

2023年4月21日 The Pelletizing Process. The production of iron ore pellets from fines to finished product can differ based on a variety of factors. As such, it’s important to note

Read More

2016年10月13日 The main unit operations of pelletizing process are grinding, filtering, pressing, pelletizing, and firing. ... The main objectives of this study are to know the

Read More

2021年3月15日 This part describes the history, goals of pelletization, and provides a framework so that the chemical factors leading into an effective pelletizing process can be understood. The general overview of binders is covered to provide an outline of what binding mechanisms are present, but details regarding specific binders will be explicated further ...

Read More

2015年1月1日 The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price. Binders accomplish two very important functions in iron ore pelletization: .

Read More

Sintering and pelletization processes are largely influenced by the source of iron ore and the way in which the beneficiation flowsheet is adopted. The beneficiation and agglomeration processes largely depend on the mineralogical characteristics of the ore. The beneficiation and agglomeration treatment selection depends on the nature of the ...

Read More

2022年5月5日 The pelletizing process, where the crude ore from the mine is upgraded, involves several steps, including grinding, balling, and induration; see Figure 1 to the left. In the grate-kiln induration process []—see Figure 1 to the right—the sintering is mainly taking place in a rotary kiln, where the pellets increase their strength and metallurgical properties.

Read More

2019年9月4日 2.1.1 Technological Scheme of the Production of Pellets. Pellets are spherical solid bodies obtained by the granulation of finely divided iron ore materials with the addition of binder and fluxing components (or without them), followed by strengthening [].Production of pellets (pelletizing Footnote 1) is the process of converting dispersed iron

Read More

2011年1月6日 iron ore. His process involved grinding taconite to remove gangues and upgrading the iron ore (i.e., an ore beneficiation process). The resultant high-grade ore is in the form of fine particles, as small as 0.1mm or less, which are not suitable for sintering. This issue led to the use of pelletizing. Pelletizing plants are expected to play an

Read More

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heat. Before being delivered to the sinter machine, the ore mixture is ...

Read More

2016年10月13日 The main unit operations of pelletizing process are grinding, filtering, pressing, pelletizing, and firing. ... The main objectives of this study are to know the behavior of iron ore mixtures with different grindability indexes in the industrial plant and develop a regression model that can be used for real-time measurement of PS and BI for ...

Read More

2017年3月13日 The pelletizing process consists of three stages: (1) mixing of the raw material to produce the raw pellet, (2) pellet enlargement, and (3) pellet hardening. During the pelletizing, the atomized water was added in the area of disc pelletizer. ... Z. L. Xue, “Study on the shock temperature of iron ore green pellets,” Journal of Wuhan Iron ...

Read More

2012年10月1日 Iron ore pelletization. ... Figure 1. Schematic of the two principle pelletizing processes: (a) straight grate pelletizing process (Mourão, 2012); (b) grate-kiln pelletizing process (, 2012 ...

Read More

2019年9月4日 2.1.1 Technological Scheme of the Production of Pellets. Pellets are spherical solid bodies obtained by the granulation of finely divided iron ore materials with the addition of binder and fluxing components (or without them), followed by strengthening [].Production of pellets (pelletizing Footnote 1) is the process of converting dispersed iron

Read More

In a DR process, iron ore pellets and/or lump iron ores are reduced by a reducing gas to produce DRI or hot briquetted iron (HBI). Depending on the generation of the reducing gas, two different DR processes are commercially available: gas-based and coal/oil-based. ... 1.2.2.2.1.3 Pelletizing Technologies. There are two main types of pelletizer ...

Read More

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heat. Before being delivered to the sinter machine, the ore mixture is ...

Read More

2016年10月13日 The main unit operations of pelletizing process are grinding, filtering, pressing, pelletizing, and firing. ... The main objectives of this study are to know the behavior of iron ore mixtures with different grindability indexes in the industrial plant and develop a regression model that can be used for real-time measurement of PS and BI for ...

Read More

2022年11月12日 After the pelletizing process, the iron ore powder forms green pellets of uniform size. To facilitate transportation and processing, green and dry pellets must be of a certain strength. The important indicator used to evaluate the strength of green pellets is the green pellet drop number, which is generally required to be from 4–6 times ...

Read More

2017年3月13日 The pelletizing process consists of three stages: (1) mixing of the raw material to produce the raw pellet, (2) pellet enlargement, and (3) pellet hardening. During the pelletizing, the atomized water was added in the area of disc pelletizer. ... Z. L. Xue, “Study on the shock temperature of iron ore green pellets,” Journal of Wuhan Iron ...

Read More

2017年2月16日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents and solid fuel (coke). The purpose of the ...

Read More

2021年7月19日 There are six pelletizing plants at mining sites, which are technically integrated and summarized as three installations. ... 2.1 Description of the production process In the iron ore sector, iron ores and concentrates (excluding roasted iron pyrites) are produced. A distinction can be made between non-agglomerated iron ores and concentrates

Read More

2022年5月5日 This paper summarizes more than a decade of systematic studies of the flow field in an iron ore pelletizing rotary kiln using computational fluid dynamics (CFD) on simplified models of a real kiln.

Read More

2023年5月9日 Figure 2-1: The Taconite Iron Ore Pelletizing Process 2-4 Figure 2-2: Share of BF/BOPF and EAF Steel in the U.S., 2001-2021 2-9. 1-1 1 INTRODUCTION The U.S Environmental Protection Agency (EPA) is proposing amendments to the National Emissions Standards for Hazardous Air Pollutants (NESHAP) for facilities in the

Read More